Particle Size Measurement

ABLE Instruments & Controls offer JM Canty Particle Size Analysers. This technology, in its various configurations, can be deployed across a multitude of industries, such as oil and gas, pharmaceutical/biotechnology, food & beverage, chemical, glass manufacturing and foundries/metal production.

ABLE Instruments & Controls offer JM Canty Particle Size Analysers. This technology, in its various configurations, can be deployed across a multitude of industries, such as oil and gas, pharmaceutical/biotechnology, food & beverage, chemical, glass manufacturing and foundries/metal production.

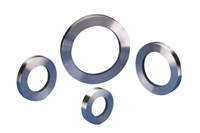

At the core of Canty’s process vision technology is an industrial camera and a high intensity LED light. Together with a Canty “FuseView” Industrial Sight Glass, this equipment affords the operator a window to a vessel, and the ability to monitor a great number of aspects of the process.

At the core of Canty’s process vision technology is an industrial camera and a high intensity LED light. Together with a Canty “FuseView” Industrial Sight Glass, this equipment affords the operator a window to a vessel, and the ability to monitor a great number of aspects of the process.

Please choose the product below that best suits your needs or call us on +44 (0) 118 9311188 for more help.

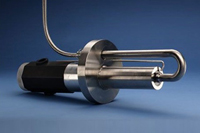

All Canty LED fibre optic light systems feature FuseView, a hermetic, fused glass, high pressure / temperature seal to completely seal the light from the process. The 316L SS or Hastelloy® design and variety of mounting connections make Canty lights ideal for any application.

The light systems facilitate view and illumination through one nozzle, saving on vessel engineering costs and the light output is cool in order to negate the possibility of denaturing the process and the potential for product bake on. With the integrated light, sight and camera arrangement, no light is lost due to reflection.

Canty provides a combined light and sight glass to optimize viewing and minimize total package cost. Illuminate through an existing sight glass or a newly installed FuseView™.

In order to accommodate a large variety of applications, such as process vessels, solid material hoppers, spray dryers, sterilizers, filters, crystallizers and centrifuges, there are a number of camera mounting options other than via a sight glass. The Canty lights are compatible with flanged, tri-clamp & NPT vessel interfaces with beam options to suit. Sanitary versions of all the sight glasses and light types are available.

J.M. CANTY Process Technology’s goal is to provide novel equipment to solve some of the most difficult challenges in process control. Their unique imaging systems have solved some of industries biggest challenges. Such is the diversity and innovative qualities of process vision that new applications are being identified and resolved on a daily basis.

Process Cameras:

For general industrial process vision applications, the Canty’s Process Camera options fall into three categories:

Vessel Cameras

This variant are patented systems designed to illuminate and view inside a pressure or process vessel through a single connection. There is no need for multiple vessel ports. Canty supplies an integrally mounted camera and lighting system (optional) in a connection as small as a 2” connection. The Ethernet video output can be displayed on a computer in the comforts of a control room or recorded on any DVR or hard drive. Various software capabilities are available to utilize closed loop control through OPC or 4-20mA outputs.

Image is of a patented Camera Light combination utilizing Gigabit Ethernet cameras and LED Lighting for superior view into pressure vessels.

Surveillance Cameras

Canty Surveillance Cameras are ideal for demanding surveillance applications, visual inspection or verification functions in extreme environments. Camera enclosures are heavy duty, weather-proof, explosion/flame proof and designed for harsh industrial environments. Fused glass provides hermetic seal of the enclosure without the need for gaskets. Canty cameras have high quality optics for optimum picture resolution. Compact and lightweight, various models feature FM, CSA approvals and are designed to ATEX standards.

Image is of a Canty Pan/Tilt/Zoom camera using a single Ethernet cable via 10/100 Mbps or optional fibre network.

High Temperature Cameras

CANTY High Temperature Cameras are perfect for challenging applications involving visual inspection or verification in extreme temperature environments. Canty High Temperature Camera Systems feature a fused glass seal standard with every model. This unique seal provides an impenetrable safety barrier to protect the camera electronics from the harsh process environment and preventing hazardous vapours from escaping into your plant.

Image is of a Canty High Temperature Camera System featuring a fused glass seal to protect the camera electronics from the harsh process environment.

Sanitary Process Camera:

The CANTY BioCamTM is a process camera engineered and designed for sanitary applications. It is the ideally suited to view inside fermentors and bioreactors, providing a continual control signal to facilitate accurate antifoam addition, thus providing significant savings in this regard. Consequently, process performance is enhanced by way of cell culture growth. The BioCamTM incorporates the latest in strobe LED lighting, which has been optimised so as not to obstruct photosensitive processes.

The BioCam™ is a sanitary Ethernet based imaging system which connects to the CANTY VCM™ image processor that determines the percentage of foam on the surface of the liquid.

Food & Beverage – Sugar Refining

While the basics of mass sugar refining have not changed significantly in the last 200 years, it is important to take advantage of relatively newer technology to allow the production processes to run more efficiently and produce a higher yield. CANTY’s range of dynamic imaging systems can be used to do just that, by providing unparalleled views into the process, and generating useful data that can be used for process control and optimization. Sugar production processes where this technology can be employed include clarifying, crystallization, centrifuging, and product quality control.

Crystallisation Monitoring – Crystal Size (SugarScope™)

The window into the crystalliser is provided by the aforementioned FuseView, which eliminates the chance of glass getting into the vessel by over torquing by the operator. It also allows for the sugar pan to pull full vacuum unlike tempered glasss. High intensity fibre-optic lighting illuminates the process and the SugarScopeTM side mounts onto the crystalliser vessel to provide live images of the sugar crystals as they grow. The system provides early detection of seeding problems, allowing for recycling of the batch if necessary without wasting energy continuing with the process.

The high-magnification lens of the SugarScope facilitates viewing of particles as small as 1 micron, with manual zoom controls to widen the viewing angle to 1000 microns.

The Cantyvision Client software allows for crystal size and shape examination, carrying out crystal distribution analysis using criteria such as Major, Minor Diameter, Area, Perimeter.

Canty provides both an OPC client and server to connect Cantyvision software to our customers’ digital control systems. This comes as standard with Cantyvision.

Other dynamic imaging sugar industry applications are:

- Clarifier Turbidity

- Centrifuge Camera Control

- Sugar Crystal Colour Analysis

Particle Size Analysis:

In its most advanced form, process vision technology can be used for particle size and distribution analysis in both liquid and solid media. For example, the InFlow™ combines the latest in microscopic CCD Ethernet camera technology with Canty fused glass developments, high intensity lighting and bespoke CANTYVISION™ Software, to provide real time, inline analysis (size and concentration) of oil and solids in water, or water and solids in oil.

Particle Size Analysis

In its most advanced form, process vision technology can be used for particle size and distribution analysis in both liquid and solid media. For example, the InFlow™ combines the latest in microscopic CCD Ethernet camera technology with Canty fused glass developments, high intensity lighting and bespoke CANTYVISION™ Software, to provide real time, inline analysis (size and concentration) of oil and solids in water, or water and solids in oil.

CANTY particle sizing analysers have been engineered to offer the user a means by which a liquid is analysed while under varying pressures, temperatures and flow rates. It offers sample or continuous, microscopic, non-destructive viewing and provides particle size analysis with two dimensional results when used in conjunction with the CantyVisionClient™ Software

Computer-Assisted Video Image Analysis software analyses each droplet and particle under 30+ visual parameters, allowing the system to differentiate between oil, solids and gas. The high-speed processor ensures all of this is done in real time.

Unlike other technologies in use in the industry, Dynamic Imaging is a direct measurement technique. It is not measuring an often unreliable related property of the process fluid, and trying to back calculate concentration or size measurements.

Various models measure 0.7 micron – 20,000 micron particles under process conditions.

Solid Particle Size Analysers:

Particle distribution by major, minor diameter, area, perimeter

The Canty SolidSizer unit is a versatile tool for lab environments to determine particle size and shape, thereby eliminating the need for sieving. The system also has multiple configurations that allow colour analysis and defect detection, as well as a tilting stage for flat particle analysis. The modular design allows for easy assembly of different configurations depending upon product type and/or analysis desired. The tilt stage feature is similar to the technology patented in the Canty RockSizer and is especially effective for analysing flat, stone-like particles. The stage is designed for both back and front lighting use.

BLACK SPECK or COLOR SPECK detection is available as an add on to a particle size and shape analyser, or as a stand-alone system. This uses a camera system with controlled front lighting system for accurate colour representation within the captured images. Multiple measurement zones can be configured to allow for detection of particles of different colours within the same product.

LabPlus SolidSizer™ with Automated Ethernet Control

Solid Particle Size Analysers

The combination of a Canty Fibre Optic Light with the digital Ethernet camera allows for optimal view into this dirty dark environment for visual verification of the flow and quality

Drilling Mud Level Measurement in the mud return line is performed using a camera system combined with an angled light source. The image analysis software tracks the edge of the shadow on the fluid surface, the position of which is relative to the fluid level within the pipeline. The fluid velocity can also be measured though a software algorithm detecting the speed of moving particles / bubbles on the fluid surface. An Identical mounting configuration to the widely used paddle system allows for easy retrofitting. The non-contact nature of the system ensures there is no issue with clogging of moving parts which is common to the paddle units, while the inbuilt jet spray ring ensures a clear view at all times. Visual verification allows for confidence in the instrument readings, while also allowing the operator to monitor for issues with the line itself.

The combination of a Canty Fibre Optic Light with the digital Ethernet camera allows for optimal view into this dirty dark environment for visual verification of the flow and quality