Industry Solutions

ABLE provide measurement solutions for many industries with our portfolio of instruments and controls, including Oil & Gas, Power and Chemical industries. Years of experience enable an inherent understanding of the requirements of these sectors and most importantly the ability to correctly apply fit for purpose equipment. Examples of the areas we serve and our application knowledge are detailed here.

Oil & Gas Solutions

Power Solutions

Chemical Solutions

Pharmaceutical Solutions

Automotive Solutions

Food Solutions

O.E.M Solutions

Renewables Solutions

Water Solutions

H.V.A.C. Solutions

The backbone of ABLEs experience, offshore and onshore oil & gas and downstream petrochemical applications have been solved many times by our application engineers. We have equipment & knowledge to measure at all points incl: mud flow, level & density; bulk and interface liquid levels; gas compression, water injection and chemical additive processes; flare gas metering; oil in water and water cut; offload metering and overboard dump; produced water and utilities; mercury vapour and gas detection; catalyst and cracker columns; even subsea applications have been solved. View Natural Gas Application Processing Map, or alternatively, our Crude Oil Processing Map

From combined heat and power (CHP) plants, to oil and coal fired, gas turbine and nuclear power stations, many complex measurement puzzles need to be solved with reliable robust equipment. Boilers, de-aerators, steam, cooling water, precipitators, fly ash, flue gas, intake and outfall are just a few of the areas and medias encountered and instrumented by ABLE over the years.

Demanding industrial sectors require high quality, reliable equipment. When measuring dangerous, toxic, noxious or lethal chemicals or those of highly unstable nature, safety in process control and shut down is of obvious importance. Achieving critical measurements of chemicals such as phenol, ammonia, chlorine, methanol, acids, solvents, latex, elastomers etc from constituent parts, through the manufacturing process (including reaction vessels) and onto safe handling and storage, ABLE has the understanding to provide the compatible solution, whether non-invasive or in contact with the process.

Active and inactive materials used in the manufacture of pharmaceuticals, cosmetics, toiletries and specialized skincare products often change hands many times prior to completion of the end product. Throughout the manufacture and distribution chain there are numerous opportunities for contamination mitigated by accurate measurement using ABLEs range of hygienic or completely non-contact measurement solutions. View typical pharmaceutical roadmap for Canty vision products here.

Throughout the changing history of the Automotive industry, critical measurement applications prevail - not only in control of production areas like paint shops (re-circulation & spray gun feed line flow; tank levels; drying environment humidity etc), but performance verification in the crucial domain of Research and Development, for example efficiency measurements on engine test beds. ABLE can offer a full range of solutions.

Many demands are made of physical measurement instrumentation due to hygiene and material compatibility with foodstuffs as well as accuracy and repeatability for recipe and batch control. Instruments from ABLE can be supplied with hygienic designs, sanitary fittings and food approvals as well as suitability to withstand clean in place procedures. Completely non-contact instrumentation can also be provided for level, flow, density and weight, plus a full range of moisture equipment to ensure cereals and powders remain in specification. View typical sugar roadmap for Canty vision products here.

O.E.M.s exist in many guises, but particular instruments such as pressure, temperature, flow & level switches and gauges lend themselves well to this sector for use on pumps, generators and other skid mounted industrial equipment as well as being integrated into systems for building management, fire protection and material handling. Re-designing or own labeling of equipment to meet an O.E.M.s requirements and supply in large quantity or against call off contracts are all within ABLEs capability.

In the field of renewable energy, our comprehensive portfolio of reliable, durable, easy-to-use products for process instrumentation and analytics provides a solid foundation for mastering the complex processes in this industry. Whether its pressure & temperature monitoring in Biogas treatment systems, mass flow measurement of the catalyst delivery system in Biodiesel distillation, or level gauging in Bioethanol fermentation & storage, ABLE has the answers. View Use of Rheonik Products in Hydrogen Processes application roadmap

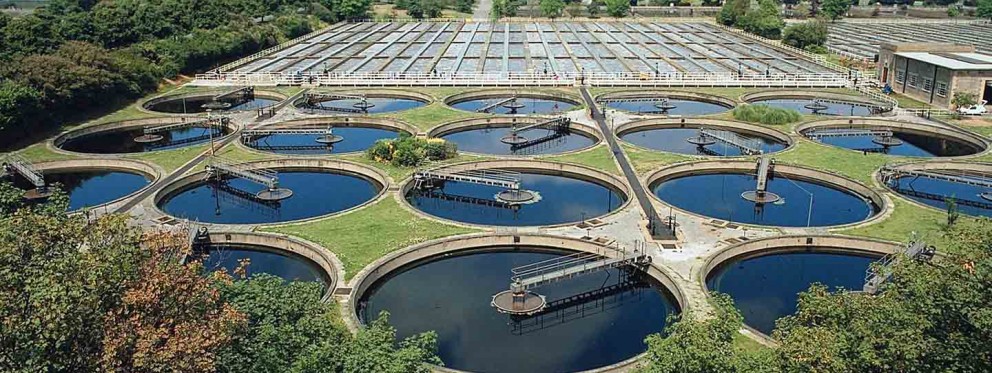

The water industry is more than just water. ABLE has significant expertise in odour detection and management for both fixed and portable installations at waste water and treatment plants. Of course the measurement of water flow and level in full and partially filled pipes, tanks, open channels, ring mains, rivers and reservoirs is also readily achieved with a variety of both contact and non-contact instrumentation.

A comprehensive range of humidity and dew point technologies, plus energy metering and water meters demonstrates ABLEs prowess in heating, ventilation and air conditioning measurements. In addition sensors for building management services (BMS) complete a full range of products specifically designed for this environment.