News

High Temperature Camera for Ethylene Cracker Furnace

Ethylene is one of the most widely used base chemicals in plastic and polymer production, with production likely to run to 150 million tonnes in 2016.

One of the first steps in its production is the “cracking” of light hydrocarbon gases (typically Ethane or Naphtha). This takes place in a cracking furnace where the gas, mixed with steam, passes through the furnace tubes and is heated to 750°-950°C, before rapid quenching (the whole process takes place in a matter of milliseconds). The Ethylene cracking furnace is the single largest energy consumer within an Ethylene plant (between 30-50% of the plant energy costs), so optimising it, and avoiding component failures is of critical importance. The single greatest cause of component failure is overheating tubes, which can lead to rupture, and possible escape of the feed stock into the firebox area of the furnace, which is not only a process issue, but also has significant safety implications.

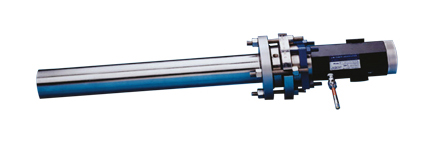

ABLE Instruments & Controls Ltd can provide Canty high temperature industrial cameras to constantly monitor the tube temperature and its position in order to detect distortion. Canty ULTRATEMP™ Cameras are ideal for demanding applications involving visual inspection or verification in extreme temperature environments.

ABLE Instruments & Controls Ltd can provide Canty high temperature industrial cameras to constantly monitor the tube temperature and its position in order to detect distortion. Canty ULTRATEMP™ Cameras are ideal for demanding applications involving visual inspection or verification in extreme temperature environments. Depending on where the camera(s) is mounted within the furnace, a view of the burners can also be provided, which will allow for individual burner optimisation. Therefore, issues such as flame detachment, smoking burners, or flame impingement onto the furnace tubes, which can lead to overheating, are negated.

Canty ULTRATEMP™ Camera Systems feature a fused glass seal standard with every model. This unique seal provides an impenetrable safety barrier to protect the camera electronics from the harsh process environment and prevents hazardous vapours from escaping into the plant.

For more information regarding this article, please contact ABLE Instruments on +44 (0)118 9311188 or by email: info@able.co.uk.