Temperature Measurement

Monitoring and analysis of temperature data is critical for predictive maintenance and for ensuring consistent plant performance. The impact of Industry 4.0 and the evolution of the smart factory is changing the demands for data from the process measuring equipment. Data is essential in the smart factory, but intelligent process information is critical to prevent excess amount of irrelevant measurement data. ABLE Instruments & Controls offer a range of temperature measurement products which meet the demands of the modern smart factory including temperature gauges, temperature transmitters & temperature switches. Choose from United Electric or Siemens.

Please choose the product below that best suits your needs or call us on +44 (0) 118 9311188 for more help.

Reliable temperature measurement plays a key role in all processing industries. Ensuring temperatures are kept between acceptable parameters through a production line enables effective quality control, energy consumption regulation and safe storage of products. However, to reap these rewards the instrumentation and sensors used must be fit for purpose.

Temperature sensors vary in accuracy and operating temperature range depending on type. Choosing the right sensor depends on the application, longevity, budget, space and accuracy requirements. For most facilities, accuracy is a priority as it leaves less room for error. For processors, fewer errors mean less wasted product and larger profits.

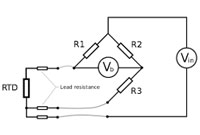

Resistor temperature detector (RTD) sensors are a popular option. The material is usually made from a pure metal and has an accurate resistance-temperature relationship to provide an indication of temperature. RTD sensors are fragile and often housed in protective probes.

Resistor temperature detector (RTD) sensors are a popular option. The material is usually made from a pure metal and has an accurate resistance-temperature relationship to provide an indication of temperature. RTD sensors are fragile and often housed in protective probes.

As they have higher accuracy and repeatability, RTDs are slowly replacing traditional thermocouples in industrial applications below 600°C. Thermocouples are sensors that produce a temperature-dependent voltage as an indicator of temperature. These devices are an inexpensive and interchangeable option. However, achieving system errors of less than 1 degree Celsius is difficult. In today’s data-driven factories, this limits the ability to process and analyse data correctly.

As they have higher accuracy and repeatability, RTDs are slowly replacing traditional thermocouples in industrial applications below 600°C. Thermocouples are sensors that produce a temperature-dependent voltage as an indicator of temperature. These devices are an inexpensive and interchangeable option. However, achieving system errors of less than 1 degree Celsius is difficult. In today’s data-driven factories, this limits the ability to process and analyse data correctly.

For greater precision, thermistors are available. This sensor type produces resistance dependent on temperature, to a much greater sensitivity than standard resistors. The temperature indication from a thermistor is precise but can only be achieved within a limited temperature range, typically between -90 to 130°C.

![]() Semiconductor temperature sensors are another option with temperate limitations, operating from -50 to 150°C. These sensors are manufactured in an identical fashion to present-day electronic semiconductor devices like microprocessors, built upon thin silicon wafers. These temperature sensors enable simple interfacing with other electronic devices, including amplifiers, regulators and microcontrollers.

Semiconductor temperature sensors are another option with temperate limitations, operating from -50 to 150°C. These sensors are manufactured in an identical fashion to present-day electronic semiconductor devices like microprocessors, built upon thin silicon wafers. These temperature sensors enable simple interfacing with other electronic devices, including amplifiers, regulators and microcontrollers.

For modern factories, this integration is important. It shows the general trend of temperature measurement technology, and its relation to other equipment in a processing plant. Temperature regulation is more than informing an operator on the temperature of a product. It is also automating a chain of events to correct discrepancies, raise alarms and record such changes.

For example, Oil, gas and petrochemical processes are undertaken at specific temperatures. In industrial applications such as these, gaseous or liquid fluids may be heated or cooled. This duty is undertaken in a heat exchanger, whereby the fluid is heated or cooled by heat transfer with a second fluid such as water, glycol, hot oil or another process fluid (the heating or cooling medium). Temperature control is used to maintain the desired temperature of the first fluid. A temperature sensor transmitter (TT) is located in the first fluid at its outlet from the heat exchanger. This measured temperature is fed to the temperature controller (TIC) where it is compared to the desired set point temperature. The output of the controller, which is related to the difference between the measured variable and the set point, is fed to a control valve (TCV) in the second fluid to adjust the flow of the heating or cooling medium. In the case of a fluid being cooled, if the temperature of the fluid rises the temperature controller acts to open the TCV increasing the flow of the cooling medium which increases the heat transfer and reduces the temperature of the first fluid. Conversely if the temperature falls the controller acts to close the TCV which reduces the heat transfer increasing the temperature of the first fluid. In the case of heating medium with the falling temperature of the first fluid the controller would act to open the TCV to increase the flow of heating medium thereby raising the temperature of the first fluid. The controller (TIC) may also generate high (TAH) and low temperature (TAL) alarms to warn operating personnel of a potential problem.

As previously stated, temperature is one of the most common measured physical quantities across the industries. The following examples stand as testimony to this:

Temperature Control in Food Processing Applications

While thermocouples often can be found in small-scale, low volume, commercial restaurant-grade appliances, they also can be found as part of the food production process. Typical industrial process cooking equipment that employs temperature-sensing probes include ovens, warmers, fryers, toasters and grills.

Temperature sensors for the food industry need to provide consistent temperature readings to ensure precise cooking, frying or heating and protect food from being over- or undercooked. In addition to cooking equipment, it is not uncommon to find thermocouples in food packaging equipment.

- Deep Fat Fryers

- Pastry Ovens

- Cookers, Steam-Jacketed Kettles and other Electrical Heater Configurations

- Walk-In Type Cold Storage

- Chocolate Tempering

- Shrink Film Packaging Systems

- Blister Packaging

- Thermoforming

- Horizontal Form/Fill/Seal Machines

- Snack Foods Packaging

Fryers contain a reservoir of oil into which wire baskets are lowered or through which a wire conveyor is drawn. Most systems use electric heaters — either mounted around the outside or immersed into the tank. The thermocouple is immersed in the oil through the side of the tank or suspended over it. Occasionally, the probe is tacked to the frying vessel wall to reduce damage.

Smaller pastry ovens require simple controllers — usually a non-indicating type. As the pastry oven chamber size increases, the features on the controller normally improve. Larger pastry oven systems typically use natural gas because of the lower operating cost, so controllers for these larger gas-fired systems will be either differential (deadband) or fully proportional (4 to 20 mA) type. Food processing applications for RTDs might include brewing, bottling, canning, pasteurization and refrigeration.

Smaller pastry ovens require simple controllers — usually a non-indicating type. As the pastry oven chamber size increases, the features on the controller normally improve. Larger pastry oven systems typically use natural gas because of the lower operating cost, so controllers for these larger gas-fired systems will be either differential (deadband) or fully proportional (4 to 20 mA) type. Food processing applications for RTDs might include brewing, bottling, canning, pasteurization and refrigeration.

This type of cooking equipment usually consists of a kettle with an exterior jacket though which steam flows to heat the kettle contents. The sensor normally is inserted into the process, but it also may be strapped to the outside of the vessel. Stirring the process mixture in the kettle provides more even heating and a more consistent temperature. Electric heaters also can be used to heat kettles or tanks. Typically, they are mounted either on the outside of the tank, inserted through the side or hung from the top. The temperature sensor is placed in the process mixture.

Food manufacturers and some drug manufacturers frequently require a large cold room for storage of products before shipment. These systems normally need cooling only (on-off type), but they also may use heat in certain geographic locations. The temperature sensors are located in the storage space.

Chocolate tempering melters and automatic coating systems require more accurate temperature control than most industrial and food processes. Because tolerances of ±0.5°F (0.2778°C) are required, an RTD sensor normally is used. Typically, electric heat with an SCR or solid-state relay is best suited to this type of localized heating.

Chocolate tempering melters and automatic coating systems require more accurate temperature control than most industrial and food processes. Because tolerances of ±0.5°F (0.2778°C) are required, an RTD sensor normally is used. Typically, electric heat with an SCR or solid-state relay is best suited to this type of localized heating.

Other areas of the chocolate, fudge and candy market use low cost thermostats in melting and cooking kettles. Several manufacturing processes are used to make plastics goods, and many employ the use of thermocouples and RTDs for accurate temperature measurements.

Heating tunnels with various styles of heaters are used to shrink plastic film around food packages. Sensor placement can be either in the airstream or on the heater. In addition, often a film-tacking assembly is placed before the heating tunnel. That equipment typically will utilize controller or other low-cost temperature device.

Hard plastic protective covers are formed via vacuum-forming machines, which require a heat source to soften the plastic sheeting before a vacuum “pulls” it to the mould and forms the final shape.

Heated presses also are used to form blister packaging. Products are placed on cards, usually cardboard, covered with a “plastic bubble,” placed in a press and sealed. The press may or may not use heat. Wherever there is a heated surface in the system, there will be a thermocouple located on or in that surface to measure the temperature.

In thermoforming, structured foam and plastic sheeting are heated and pressed into moulded shapes to be used for food packaging. This type of package is common in egg cartons and fast food containers. Heat is used in the preheat section and can be used on the mould itself. Wherever heat is being applied in the process, a thermocouple is used to measure the temperature and feed that reading into the process control loop.

These general-purpose packaging machines are well adapted to food products packaged in plastic film. Such normally solid items — pastry cakes, blocks of cheese, frozen items and the like — can be moved on a horizontal conveyor without separating. Heat is required in two places:

? The back fin seal, which is along the back of the package.

? The end seal bars, which form the package ends. This is also where the packages are cut apart.

Sliprings normally are used on form, fill and seal (FFS) machines to bring power as well as the sensor or thermocouple leads out of the rotating seal bars.

This segment of the food market includes packaging products such as potato chips, candy bars and pretzels. Two machine formats handle the majority of this market — horizontal and vertical form factors — and both use similar sealing techniques. These include the back seam, which seals the ends of the package and separates it from the next package. Solid snacks such as candy bars and individual packs of crackers are sealed on a horizontal FFS machine. The horizontal machines use rotary seal bars with the sensor and power leads brought out through sliprings.

Products that are sold by volume usually are packaged in a vertical FFS machine. The vertical format takes advantage of gravity to pull the product into the package. The vertical machines use fixed back-seam and end-seam seal bars that close, pull the package down, open, move up and close again repetitively.

Regardless of format, temperature-sensing probes and heaters are located in the seal bars. The more sophisticated machine models integrate all machine functions into a single microprocessor with a screen to display readings, settings and menus. Even in such systems, thermocouples or RTD sensors are used for measuring the temperature readings.

Temperature Control in Plastics Processing Applications

- Injection-Moulding Machines

- Extruders

- Thermoforming Machinery

- Pellet Dryers

Most thermoplastic materials are moulded by the injection-moulding process: the polymer is preheated in a cylindrical chamber, to a temperature at which it will flow, before it is forced into a relatively cold, closed mould cavity. High pressures are required to feed the molten polymer into the mould, and these typically are achieved by a reciprocating screw. After the polymer melt has solidified in the cool mould, the screw rotates backward to ready the next charge of polymer for the next cycle. In the meantime, the mould opens, and the finished product is removed.

Temperature sensors are located throughout the injection-moulding equipment: from the heated barrel to the mould itself as well as in the mould-cooling medium. Typically, the sensors are Type J thermocouples. The controller type varies with the barrel size, but most plastics machinery requires PID control.

In much the same way that injection-moulding machinery uses a heated screw feed, extruders use the same principle to melt plastic and force it through a die that give the material its final shape. Many continuous shapes can be achieved. Some systems consist of a screw enclosed in barrels, around which are mounted multiple band heaters. Large extruders use cast-in heaters that include two halves that bolt together; these usually include both a heater and a cooling water or oil channel.

Temperature sensors — usually Type J thermocouples — are mounted against the outside of the barrel using a spring assembly. Controller type varies as the size of the barrel increases. This is primarily due to the large amount of friction generated in larger machines, which require cooling.

In the thermoforming process, sheets of plastic, foam or any other heat-sensitive material are heated until pliable in a preheating rack and then conveyed into one of two types of presses to form the final plastic shape. The first type is a mould composed of two heated halves. They close, forming a package such as an egg carton. The second type is a vacuum-forming operation. In these systems, the one-piece mould is positioned under the preheater. Small holes in the face of the mould are connected to a vacuum pump. Once the sheet is pliable, the mould is moved into position. A vacuum is drawn that pulls the pliable material into the desired form.

In both types of thermoforming machinery, thermocouples typically are located in the moulds. The controllers are usually proportional only.

Moisture creates problems during plastics processing. It can cause poor or inconsistent quality in the final product. For this reason, dryers are used to remove moisture from the plastic pellets before they are melted. These systems typically consist of an air heater, a blower and a proportional-only controller with a Type J thermocouple in the airflow.

Moisture creates problems during plastics processing. It can cause poor or inconsistent quality in the final product. For this reason, dryers are used to remove moisture from the plastic pellets before they are melted. These systems typically consist of an air heater, a blower and a proportional-only controller with a Type J thermocouple in the airflow.

The furnace conditions to which the thermocouple will be exposed determine the proper thermocouple choice for the application.

Temperature Control in Metals Manufacturing and Fabrication

- Heat Treating

- Annealing Welds

Heat treating is an industrial thermal metalworking processes used to alter the physical — and, sometimes, chemical — properties of a material. Heat treating requires that the furnace be held at a predetermined temperature for a precise amount of time in order to yield the desired depth of hardening. Such systems usually include a timer that is interlocked with the controller’s alarm to sound when the temperature is reached. Other than this special feature, the furnaces follow conventional designs.

Annealing is a metalworking heat treatment that alters the physical — and, occasionally, chemical — properties to increase the material’s ductility and reduce its hardness, making it more workable. It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time, and then cooling. Welded pipelines that must be annealed to ensure rated strength and flexibility are a good example.

Typical annealing systems include a portable electric heater that is strapped around a weld, a thermocouple that is tack welded to the pipe, a proportional controller and a ramp generator for the setpoint. The temperature must be brought to setpoint and held without interruption; otherwise, the process must be restarted.

Typical annealing systems include a portable electric heater that is strapped around a weld, a thermocouple that is tack welded to the pipe, a proportional controller and a ramp generator for the setpoint. The temperature must be brought to setpoint and held without interruption; otherwise, the process must be restarted.

Chambers for sterilization are common on pharmaceutical production lines. High accuracy requirements usually dictate the use of an RTD sensor and a proportional or PID-type controller.

Temperature Control in Pharmaceutical Manufacturing

- Package Machines

- Sterilizers

- Manufacturing Processing

The most common package that requires heat in the drug industry is shrink packaging used for individual packages and packaging for quantities of an item to be shipped to distribution points. This type of package has become popular with the concern over tamperproof packaging.

System configurations can vary dramatically, but process controls for most systems usually consist of an air circulation heater, a thermocouple located at the exit from the heater, and a proportional-only controller. The heated air is applied to the package, which has heat-sensitive film loosely tacked in place. The film shrinks tightly when heat is applied, securing the package and making it evident if tampering occurs.

Chambers for sterilization are common on pharmaceutical production lines. They typically use steam for sterilization. High accuracy requirements usually dictate the use of an RTD sensor and a proportional or PID-type controller. Modern sterilizers will use multiple RTDs in the drain line to monitor the sterilizer chamber and another RTD in the heating jacket. These will work together to provide precise process control.

Pharmaceutical manufacturing employs many different physical processes such as fermentation, heating, granulation, blending, filtration, chemical extraction, tableting, compression, coating and drying. Many of these processes involve the application or removal of heat, for which thermocouples will be used to measure and provide feedback to the process controllers.

Where temperature measurement is critical and high accuracy is a process requirement, RTDs will be used in place of thermocouples. As always, placement, construction and configuration of these thermocouples will be dependent upon the individual application.

There is an exhaustive list of industries and applications that need and use thermocouples and RTDs, so this article only scratches the surface. It should, however, provide a basic background of the technology and the ways in which temperature-sensing devices are employed to create better end products in the process industries.

ABLE Instruments & United Electric Controls – a 35-year relationship

ABLE Instruments & United Electric Controls – a 35-year relationship

While thermocouples often can be found in small-scale, low volume, commercial restaurant-grade appliances, they also can be found as part of the food production process. Typical industrial process cooking equipment that employs temperature-sensing probes include ovens, warmers, fryers, toasters and grills.

United Electric Controls (UE) provides safety, alarm, and emergency shutdown solutions (ESD) that reduce complexity, simplify installation, and achieve regulatory compliance. The company provides wirelessHART gas leak detectors, pressure switches, temperature switches, electronic smart switches, safety switches, safety transmitters, and sensors for the process, discrete, semiconductor, aerospace, and defence industries.

United Electric Controls (UE) provides temperature switches, pressure switches, electronic pressure switches, differential pressure and temperature transmitters, wireless gas detectors, temperature sensors, and controls for critical safety, alarm and emergency shutdown (ESD) functions demanded by the process industries and mission-critical applications.

With over 80 years of knowledge designed into their application-specific products, customers are assured of out-of-the box performance and reliability.

UE’s smart electronic temperature switches and pressure switches combine a switch, gauge, and transmitter in a rugged instrument with no moving parts. They go beyond the mechanical switch to eliminate operating risk and increase system reliability.

SIL Certified Products:

UE manufacture many different SIL 2 certified products. Their products are designed with safety in mind, and they offer sensors that are certified to IEC 61508 standard. The UE product portfolio has 4 SIL 2 certified and SIL 3 Capable products, the 12 series, the 100 Series, The One Series Field Safety Transmitter and the 120 Series.

The One Series Safety Transmitter is a pressure or temperature monitoring transmitter switch that provides a NAMUR NE 43 standard 4-20 mA analog output. Its programmable high-capacity solid-state safety relay output enables the fastest emergency shutdowns.

The One Series Safety Transmitter is certified for use in SIL 2 functional safety applications (HFT = 0) and is capable of SIL 3 applications when augmented by redundancy and voting logic. Its simple design means fewer nuisance trips — for greater safety, productivity, and throughput.

The One Series Safety Transmitter is certified for use in SIL 2 functional safety applications (HFT = 0) and is capable of SIL 3 applications when augmented by redundancy and voting logic. Its simple design means fewer nuisance trips — for greater safety, productivity, and throughput.

Heat Trace Solutions:

Electrical heat tracing is used throughout most process plants, power plants and wastewater treatment facilities to keep piping and vessels from freezing during cold weather. It is also used where processes require materials to be at an elevated temperature.

Hazardous Location:

Pressure, Differential Pressure, and Temperature Switches

United Electric Controls hazardous location pressure & temperature switches are explosion-proof, hermetically sealed and approved for use in hazardous locations worldwide where explosive or corrosive atmospheres exist. Their pressure & temperature switches are used in hazardous locations for oil & gas, refineries and petrochemical applications where critical safety, alarm and shutdown functions. are required.

United Electric Controls hazardous location pressure & temperature switches are explosion-proof, hermetically sealed and approved for use in hazardous locations worldwide where explosive or corrosive atmospheres exist. Their pressure & temperature switches are used in hazardous locations for oil & gas, refineries and petrochemical applications where critical safety, alarm and shutdown functions. are required.

General Purpose

United Electric has a wide array of ordinary location industrial switches for general purpose: vacuum, pressure, differential pressure and temperature switches. The Excela is an easy to install electronic switch, the first of its kind. Designed to give plant operators an affordable way to upgrade to electronic performance, Excela has only two wires, so it can be easily dropped into existing mechanical switch infrastructure. In fact, this innovative, high-quality electronic pressure and temperature switch delivers everything operators need for better performance at an affordable price.

United Electric has a wide array of ordinary location industrial switches for general purpose: vacuum, pressure, differential pressure and temperature switches. The Excela is an easy to install electronic switch, the first of its kind. Designed to give plant operators an affordable way to upgrade to electronic performance, Excela has only two wires, so it can be easily dropped into existing mechanical switch infrastructure. In fact, this innovative, high-quality electronic pressure and temperature switch delivers everything operators need for better performance at an affordable price.

Temperature Sensors & Transmitters

UE are a major manufacturer of industrial temperature sensors, thermocouples, resistance temperature sensors (RTD’s), thermistors, and other types of sensor assemblies. ISO 9001-certified and a leading practitioner of Lean Manufacturing methods, they focus on building high-quality, high-reliability temperature sensor products for the industrial market. Their expertise covers a wide variety of applications — from lab equipment to road-making equipment, from the blast furnace to the blast chiller, and everything in between.